Upstream

ProMax® is a comprehensive simulation resource capable of modeling oil and gas systems from the well-head to delivery, all in a single simulation!

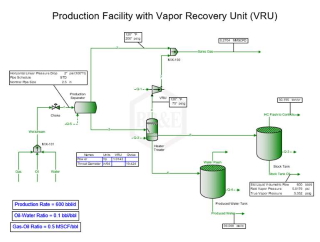

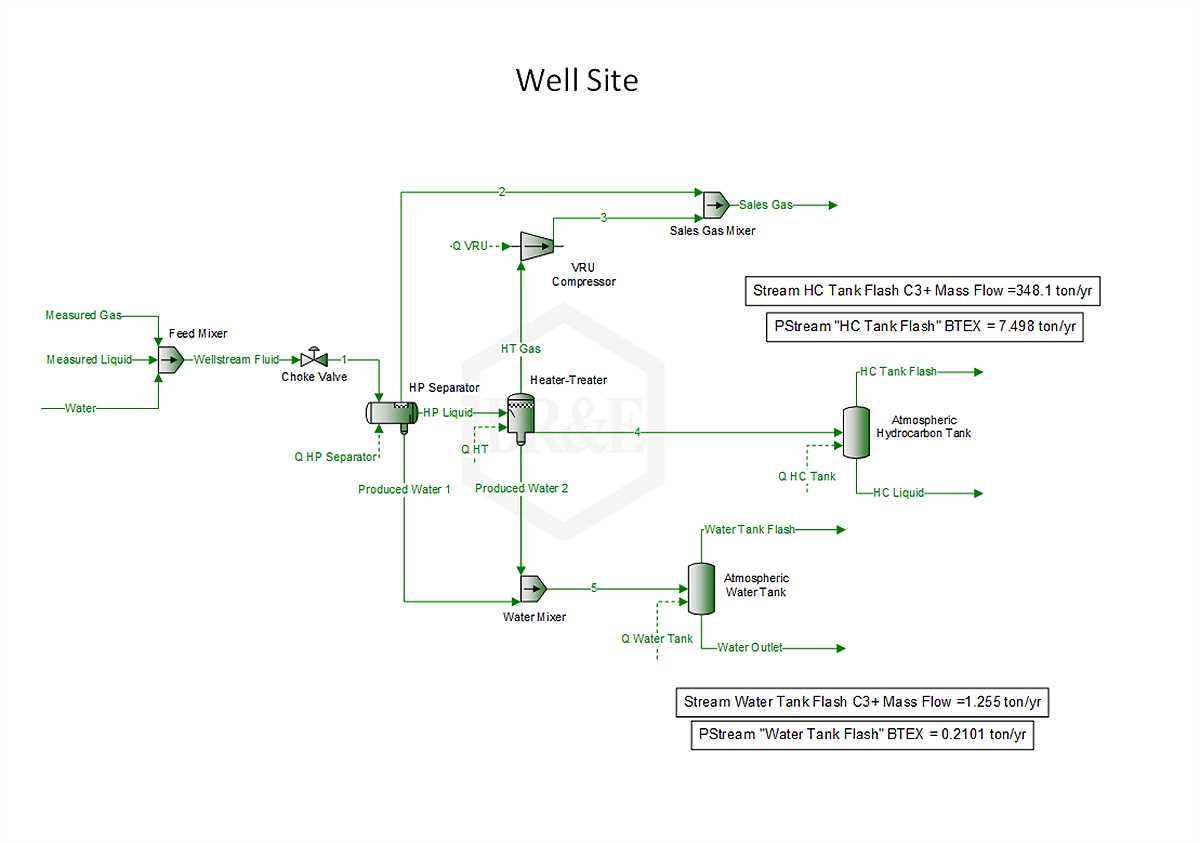

The first step in processing is the Production Facility where the entire system can be modeled including the safety system and even the tank battery vent lines!

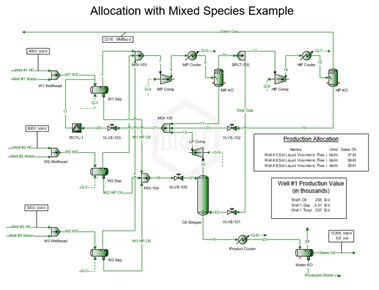

When reservoir fluids from various wells are comingled in a production facility, determining the original source of the hydrocarbons is extremely important. Operators need to know whether the fluids from a given well are sold at fuel value or more valuable liquids products to properly allocate proceeds to the respective royalty interests of each well.

ProMax makes the process incredibly simple while providing a high fidelity model adhering strictly to first principles.

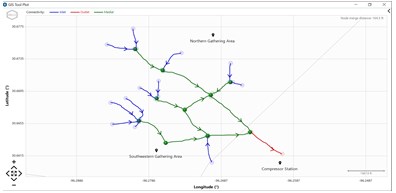

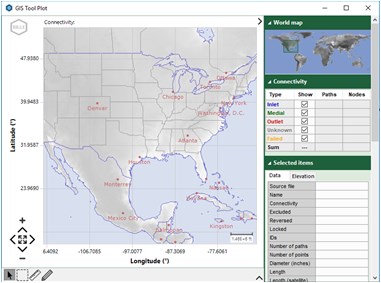

Easily model compression trains, gathering systems, or saltwater disposal systems using accurate, robust models. With ProMax, you can quickly determine pressure drop, heat transfer, and location of any condensate whether the pipe is buried, above ground, or subsea. Set up is made even easier with the GIS Tool to import from kmz or shape files.

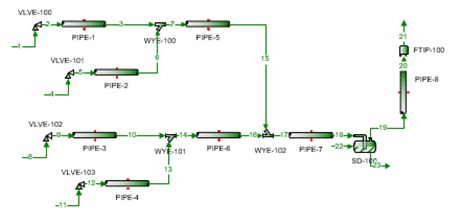

ProMax allows the user to design and trouble shoot vent systems, regardless of whether they are high or low pressure. From PSV to the flare tip, flare systems can be easily built and analyzed in ProMax.

Very low pressure systems can be modeled as well, including vent lines from atmospheric tanks. The ProMax OOOOa Vent Assessment Tool™ allows for fast, efficient design and validation of these systems.

Quickly and easily construct complex pipeline models from GIS data using the ProMax GIS Tool!

The GIS Tool also allows for convenient, global viewing and editing of pipeline properties in a simulation using a simple table called the Flowsheet Tool.

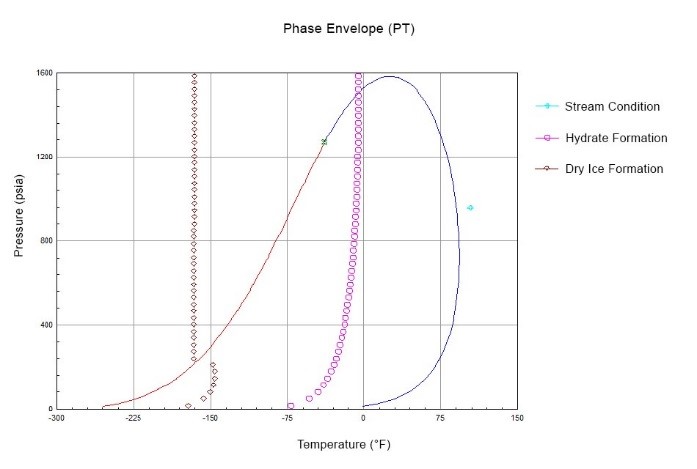

Model dehydration and hydrate suppression with confidence using the leading resource in the industry. Accurately simulate almost any dehydration flow scheme, and precisely calculate the amount of methanol or glycol required to get the freeze temperatures you need.

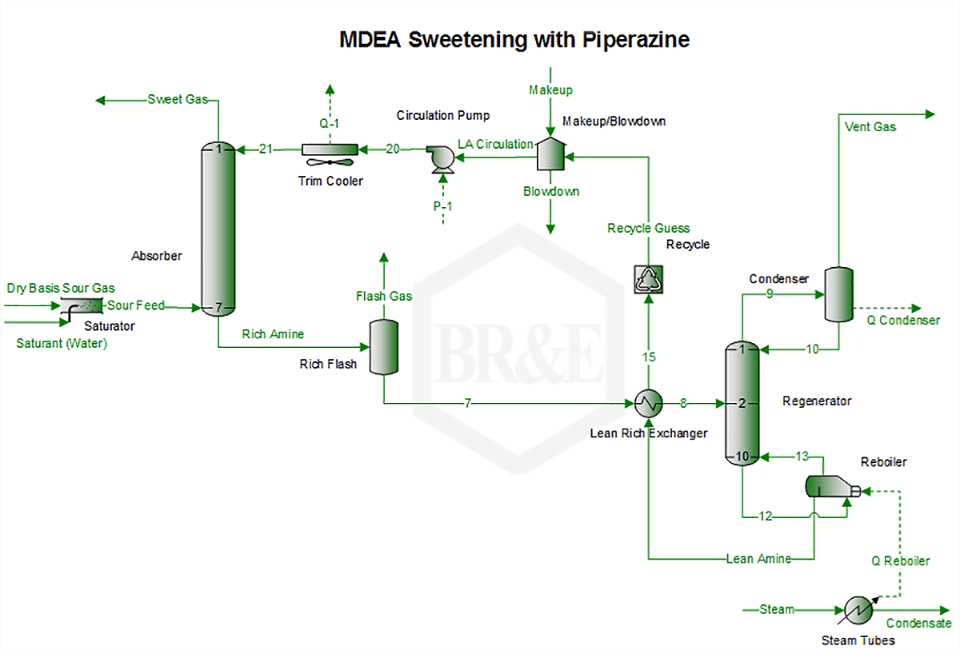

For over 40 years, BR&E has been known as the industry leader for simulating acid gas removal systems. ProMax continues this legacy and is the most versatile and complete package available for a variety of acid gas removal systems, all of which can be directly integrated with your other hydrocarbon processing systems in one simulation file!

ProMax is well known for its ability to accurately predict BTEX and VOC absorption and emissions from oil and gas facilities. ProMax comes with a variety of tools to facilitate reporting emissions of these compounds as well as HAPs, Greenhouse Gases, and Global Warming Potential. These tools work seamlessly with your ProMax models to combine process simulation and environmental reporting in one software package. Microsoft Excel® connectivity facilitates automation and customizable reporting.