Acid Gas Removal

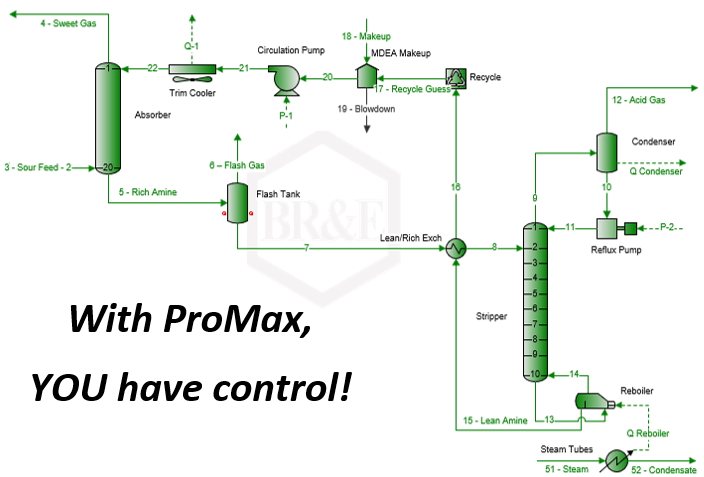

ProMax® is the leading software in industry for modeling acid gas removal systems. Building on almost 50 years of simulation experience, ProMax offers the highest degree of accuracy, flexibility, robustness, and ease-of-use available today. ProMax contains all of the prerequisites for predictive simulation of these units out-of-the-box, including advanced thermodynamics, specialized distillation column modeling, and refined chemical reaction kinetics. User Defined customizations are also available.

Available Solvents in ProMax

Amine Based Solvents

ProMax offers the most comprehensive suite of generic and proprietary amine-based solvents on the market today.

Generic Amine Based Solvents

MEA, DEA, TEA, AEE, MDEA, DIPA, AMP, any blend of amines with or without additives, degradation products, and heat stable salts

Branded and Proprietary Solvents

Huntsman Jefftreat®

MS-100, MS-203, MS-205, MS-300, M-505, M-510, M

Huntsman DGA® Agent

DOW Ucarsol™

HS-103, AP-804, AP-806, AP-810, AP-814, HS-101, HS-115, AP-802, LE-713, LE-777, LE-801

Eastman AdapT

100, 110, 115, 201, and 203

Shell Sulfinol® (Shell Sulfinol Licensors and Licensees Only)

Additives and Other Components

Operating units often contain other species in the solvent blend such as degradation products, heat stable salts, and additives. Include these with your amine or amine blend for an accurate and realistic representation of solvent performance.

Degradation products including bicine, DEEA, and DMEA

Heat Stable Salts from acids such thiocyanic acid, oxalic acid, glycolic acid and others that are typically presented in amine analyses or appear in operating amine systems.

Additives such as piperazine (activator) and phosphoric acid (protonator)

Physical Solvents

Along with amine-based solvents, ProMax can accurately model the performance of various physical solvent systems including DEPG (Coastal AGR), NMP, Methanol (Rectisol), and Propylene Carbonate (Fluor Solvent).

Other Treating Processes

Amino Acids Salts with glycine, sarcosine, and l-proline

Potassium Carbonate with or without activation.

Thermodynamics

The foundation of any good simulator is accurate thermodynamics containing the latest VLE and VLLE data available. ProMax contains over 40 years of engineering judgement, experience, and development in its proprietary Electrolytic-ELR model, which is updated constantly. The Electrolytic-ELR model is capable of handling any number of available amines, amino acids, additives, heat stable salts, and other components.

And while accurate phase equilibrium is important, accurate physical properties are also critical for calculating various unit operations, including heat exchangers, distillation columns, pipelines, and more. The Electrolytic-ELR model contains excellent predictions for heat capacities, viscosities, densities, thermal conductivities, diffusivities for these non-ideal systems.

Mass + Heat Transfer Models

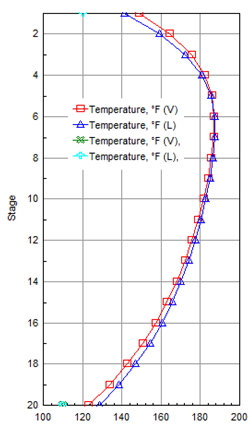

Introduced in ProMax 4.0, ProMax’s Mass + Heat Transfer model provides rigorous and accurate predictions of contactors and regenerators. Coupled with excellent phase equilibria and physical property predictions, the Mass + Heat Transfer model provides superb predictions for a range of reactive and non-reactive systems. Simply put in the actual equipment in the design or operating unit and let ProMax do the rest!

Trays

The Mass + Heat Transfer model allows for the use of real trays for predictive results. Simply insert the exact number of trays in the model, the appropriate tray type (sieve, valve, or bubble cap), and the exact tray geometry desired.

Packing

ProMax includes a comprehensive offering of both random and structured packings, including those from major vendors such as Pall, Koch, Sulzer, Raschig, and others. A large selection of both random and structured packings are available by default. The user can insert their own custom packings as well. The Mass + Heat Transfer model will calculate the column hydraulics, including pressure drop and flooding, as well as mass and heat transfer between the phases throughout the column.

Reaction Kinetics

Whether the column internals contain trays, packing, or a combination of the two, the rate of chemical reactions of some components plays a critical role in mass transfer. To account for this, accurate and refined kinetics are required. ProMax contains kinetic rates for BOTH CO2 and COS in amine systems.

With ProMax, the User has control

Mass + Heat Transfer model selections

The implementation of the Mass + Heat Transfer is comprehensive. While ProMax automatically provides recommended default selections, the user has additional options to choose from if they desire.

Mass Transfer Formulation

General Maxwell-Stefan, Overall Vapor Phase, Overall Liquid Phase, Maxwell Stefan Liquid Only, Maxwell Stefan Vapor Only

Mass Transfer Coefficient Models

Trays (Stichlmair, Zuiderweg, Chan-Fair, AIChE, Chen-Chuang, Scheffe-Weiland, User Defined)

Random Packing (Onda, Billet-Schultes, Bravo-Fair, Hanley-Chen, Raschig*, User Defined)

Structured Packing (Billet-Schultes, Rocha-Bravo-Fair, Hanley-Chen, User Defined)

*Raschig packings only

Interfacial Area Models for Trays

Stichlmair, Zuiderweg, Scheff-Weiland, User Defined**

**As part of User Defined Mass Transfer correlation

Mixing Models

Well Mixed, Vapor Plug Flow, Liquid Plug Flow, Vapor + Liquid Plug Flow

Adjustment Factors

Heat Transfer Factor, Interfacial Area Factor, Component based mass transfer multipliers

User Defined Selections

For developers of new solvents and equipment, ProMax is the go-to tool that provides the power and flexibility to implement new methods and ideas on your own. ProMax offers the following customizations that the user can implement directly, allowing the proprietary nature of the new developments to be kept in-house and secure:

User Defined Packing

While ProMax offers an expansive offering of default packing selections, the user can also describe their own packings and implement them for both hydraulic and mass transfer calculations.

User Defined Mass Transfer Correlations

Whether it is a new mass transfer correlation for typical internals, or a correlation for column internals that do not even resemble traditional trays and packing, ProMax allows the user to input their own mass transfer correlations. This provides ease of customization of calculating mass transfer coefficients while harnessing the full power of ProMax’s advanced column calculations, providing significant benefits to developers of new mass transfer equipment.

User Defined Components

With the constant development of new solvents, users need a way to simulate new and proprietary components in a full, complete simulation. ProMax provides this with the User Defined Components feature. The user can insert components, phase equilibria, reactions, and even reaction kinetics into ProMax without the need to share or expose their intellectual property to BR&E.