Tank Losses Property Stencil

Adam Georgeson

April 26, 2013

Tank Losses Property Stencil

The ProMax Tank Losses stencil is used to estimate the rate and composition of volatile losses from a liquid storage tank. Flashing, working, breathing, and loading losses are considered. The estimation is based on ProMax thermodynamics and the Environmental Protection Agency’s AP-42 methodology.

Owing to the limitations of AP-42, the Tank Losses stencil is applicable only to liquid storage tanks operating at or near atmospheric pressure. Pressurized liquid storage tanks are not supported.

The Tank Losses stencil estimates average annual loss rate for environmental reporting applications. Design engineers sizing flares and vapor recovery units should do so according to the maximum instantaneous loss rate, not the annual average loss rate.

To open the ProMax Property Stencil in Visio 2010 and 2013, click on the "More Shapes" group in the Shapes window to the left of the flowsheet and select ProMax Property Stencil from the list. In Visio 2003 and 2007, go to File -> Shapes to select the Property Stencil.

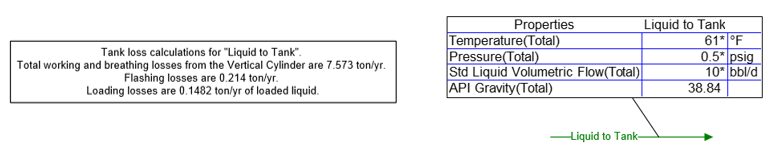

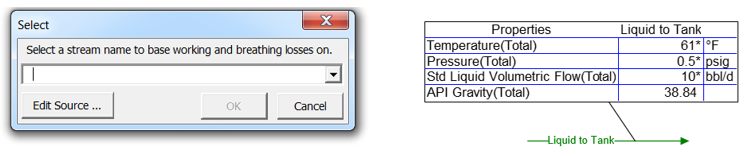

To begin, drag & drop a Tank Losses stencil onto the ProMax flowsheet, and double-click to open it. The stencil will ask for a reference stream to obtain the fluid composition. Annual net throughput is also obtained from the reference stream in units of actual volumetric flow.

|

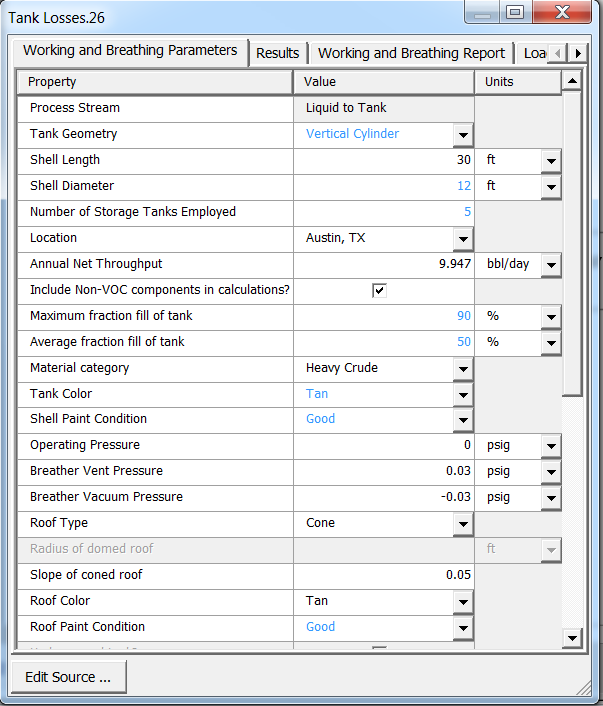

Next, enter the tank geometry, paint color and condition, operating characteristics, and location. These parameters are used to evaluate the vapor pressure and liquid surface temperature in the tank, which are used in subsequent loss calculations.

There are two material types which can be selected for any tank: heavy crude and light organics.

Note: Legislation does not provide a concise definition for either material type. Some companies designate 40o API as a standard to differentiate between heavy crude and light organics.

ProMax can accommodate multiple tanks in a battery. Inlet flow is assumed to be evenly distributed between the tanks; a calculation is performed for each individual tank, and then the results are combined.

The stencil provides results for four types of losses:

- Flash losses occur as the process fluid enters the tank.

- Working losses occur as material is added or removed from the tank.

- Breathing losses occur as the tank temperature fluctuates with the day/night cycle and the summer/winter cycle.

- Loading losses occur as material is moved from the process tank to a tank truck, rail car, or marine vessel.

|

|