Modeling a Co-Current Heat Exchanger in ProMax

Russell Burnett

May 10, 2013

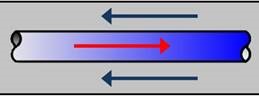

A number of factors contribute to heat exchanger performance, including the flow configuration. With a counter-current exchanger, the two fluids flow in opposite directions, while for a co-current exchanger they flow parallel to one another, as demonstrated in the diagram below.

Two flow configurations for a shell-and-tube heat exchanger: counter-current (left) and co-current (right).

Counter-current exchangers are more efficient (and therefore more common) because they maintain a larger temperature difference between the two fluids across the length of the exchanger. Nevertheless, co-current exchangers are still used on occasion, and both may be modeled accurately in ProMax.

By default, ProMax calculates heat exchanger performance using thermodynamics alone, without consideration for the flow configuration. The program assumes there is enough area within the exchanger to achieve the specified energy transfer. It then bases its warnings (e.g. end approach temperature) on a counter-current arrangement, since this is the most common configuration. The advantage to this approach is that the user can model an exchanger without having to provide sizing information. This is particularly useful in process design, where the emphasis is on what is thermodynamically possible, not on how large process equipment actually needs to be. The drawback to this approach is that the calculation is independent of the manner in which streams are connected to it; simply connecting the streams such that they appear to be running co-currently does not actually make the calculation operate in co-current mode. This is because the underlying assumption is still in effect: there is sufficient area for the requested energy transfer to occur.

The default assumption of counter-current flow is modified by providing sizing data for the exchanger, including the flow configuration. Adding this information requires ProMax to verify whether the exchanger is capable of reaching the thermodynamic heat exchange limit specified. Alternatively, it allows the heat exchange to be based upon the actual exchanger size.

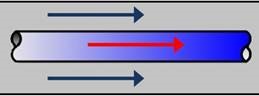

The flow configuration is specified by selecting “Enable” on the Process Data tab for the exchanger and setting the “First Tubepass Flow” parameter (under “Rating -> Overall -> Tubes”) to “Counter” or “Parallel”.

Specifying the flow configuration (counter- or co-current) in the ProMax Project Viewer.

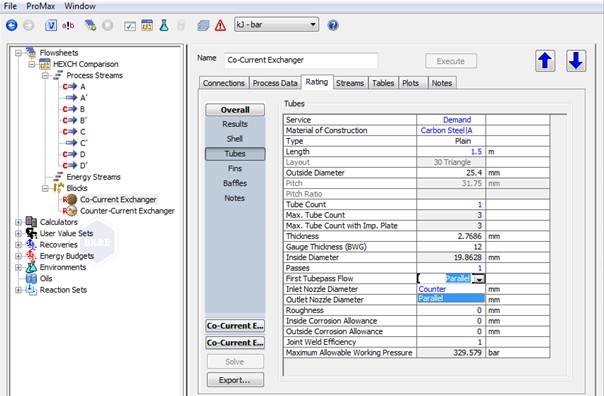

A simple ProMax project demonstrates the effect of this change. Two equally-sized single-pass shell-and-tube heat exchangers are positioned side-by-side, one with the “First Tubepass Flow” set to “Counter”, the other “Parallel”. Water is fed through all sides of each exchanger at a rate of 500 mol/hr. The shell side contains the hot water stream, while the cold water stream flows through the tube side. The tube side outlet temperature is varied until the required contact area is equal to that of the exchanger (i.e. until the fraction over design is zero). Results are shown below.

Comparison of the results for equally-sized counter- and co-current heat exchangers.

Consistent with expectation, the counter-current exchanger achieves a greater heat exchange, as evidenced by its minimum end approach temperature being about 1.2°C lower than that of the co-current exchanger.

Note that the arrows used by ProMax when plotting the supply and demand heat transfer curves always reflect counter-current flow, even when co-current flow has been specified. That is, regardless of the configuration, the supply side arrows point in one direction, and the demand side arrows point in the other.