Modeling TEG Contactors in ProMax - Recommended Practices

Lili Lyddon

June 14, 2011

BR&E recommends modeling a TEG contactor using ideal stages based on an overall column efficiency of 25-30% as stated in GPSA Engineering Data Book and other references. The 25% value is normally used so as to be on the conservative side. Thus an 8 tray contactor would be modeled as 2 ideal stages. Since Murphree Efficiencies are not the same as the overall column efficiency, using an 8 stage contactor with 25% Murphree Efficiency on all stages will NOT give the same result as a 2 ideal stage contactor. The Murphree Efficiency effects are compounded from one stage to the next.

From the ProMax Help (Stage Data Tab (Column) topic):

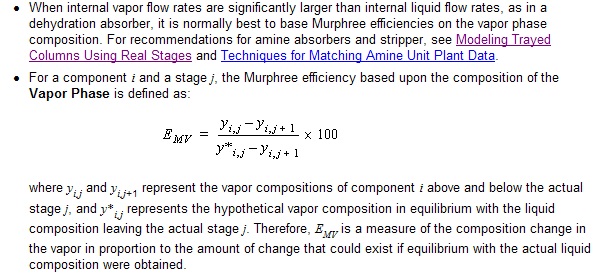

Overall Efficiency (EOC) and Murphree Efficiency (EMV) are related by:

EOC = ln /ln λ

λ = mV/L where m is the slope of the vapor-liquid equilibrium curve

Since λ is not equal to 1, EOC is not equal to EMV

Contactors with 6 and 10 trays would be the equivalent of 1.5 and 2.5 ideal stages. The half stage can be modeled by setting the Murphree Efficiencies based on the VAPOR phase on ONLY ONE of the stages to 50%. If the number of ideal stages is a whole number, Murphree efficiencies should not be used at all.

Since the vapor flow rate in a TEG contactor is considerably higher than the liquid flow rate, the Murphree Efficiencies must be based on the Vapor phase. This is set in the Process Data tab, Efficiency Phase parameter, or at the top of the Murphree Efficiencies “edit” dialog. In general, Murphree Efficiency is used only as a tool to match operating data or results from another simulation. If the user feels the need to model real trays for column sizing purposes, the Murphree Efficiency could be set to match the ideal stage result. Again, setting a Murphree Efficiency of 25% on all stages based on the vapor phase in an 8 stage contactor would result in a much higher water content in the dry gas than the 2 ideal stage column.