Introduction to Refinery Reactors (AutoKinetic® Reactors) Part 1

A new way to characterize Petroleum Fractions

Jorge Martinis, Pedro Rojas

July 18, 2016

To perform the characterization of a crude oil or petroleum fraction, the conventional approach is to split the feed into a discrete number of Oil Cuts (pseudo-components), based on a measured property, typically boiling point. This approach works well for the simulation of separation units where no chemical reaction occurs. However, in refinery reactors such as diesel hydrotreaters, catalytic reformers, and hydrocracking units, the use of conventional oil cuts is no longer applicable as they lack the necessary chemical information to properly characterize the large number of reactions.

In ProMax 4.0, a new method called Oil Speciation™ (Patent Pending) to characterize petroleum fractions in terms of species is available. The Oil Speciation block takes assay data as input and estimates a composition based on the species in the simulation environment. The Oil Speciation block uses a set of carbon-based components called compound species, which group all possible isomer arrangements with a given degree of branching into a single species. This reduces the number of species in the simulation environment to a manageable level while still containing the chemical information required to model refinery reactors and processes.

The Oil Speciation block is found in the ProMax AutoKinetic Reactors stencil.

How to properly characterize a petroleum fraction

1. Select the appropriate species set in the simulation Environment

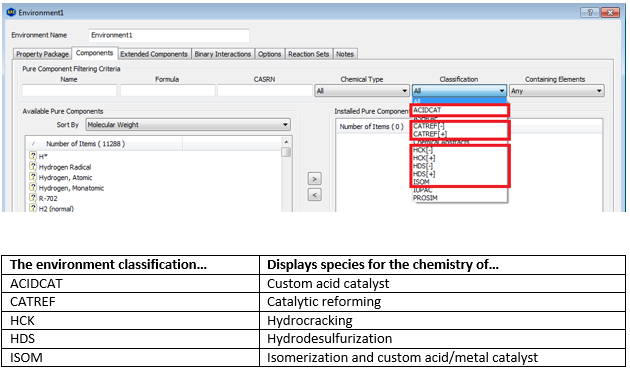

The ProMax Environment dialog contains a classification drop-down menu where the proper components for the reaction network in each kinetic model are present.

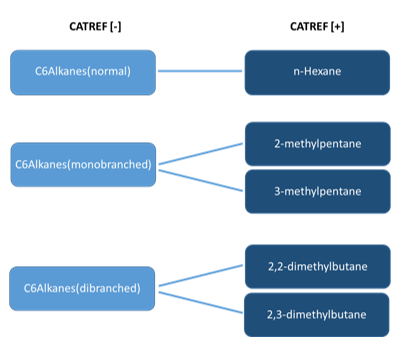

For some kinetic models there is the option of selecting between a higher resolution set of species (+) with reactive compounds represented by pure components and detailed compound species, or a lower resolution set (-) that contains a smaller number of “lumped” compound species. The decision of when to use one or the other will depend on available computing speed and the level of resolution of available experimental data. The BR&E Technical Support Team would be happy to provide further detail and guidance in selecting higher or lower resolution sets of species.

2. Input assay information in Oil Speciation block

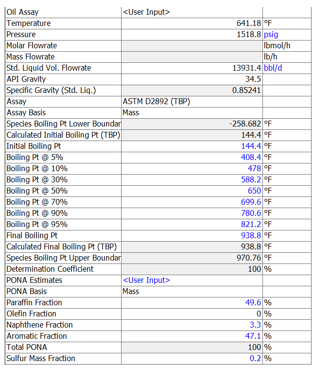

The figure below shows the input assay for a Gas Oil on the Process Data dialog in the Oil Speciation block.

The minimum required inputs are:

- Stream temperature and pressure

- Flowrate (mass, molar or std. liquid volumetric flow)

- Specific or API gravity

- Distillation curve data/type (TBP, D86, D2887, or D1160)

- Paraffin, Olefin, Naphthene, Aromatic (PONA) fractions (alternatively, the block can estimate PONA by using Riazi-Daubert API-82 method)

- Sulfur mass fraction

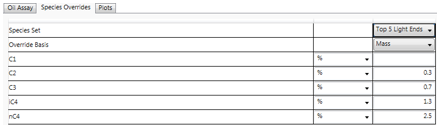

If light ends composition information is available, then the user has the option to override composition values on the species override tab of the Process Detail dialog:

3. Estimate the mixture composition

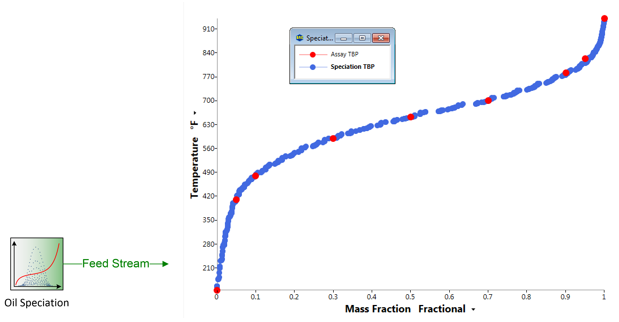

Upon execution, the output stream of the block is automatically populated with a composition, using all species available in the environment, to best match the specification data for the hydrocarbon mixture. Assay vs. speciation TBP plots are found in the plots tab in the process detail dialog to check the validity of the new composition. An example of this comparison is found below:

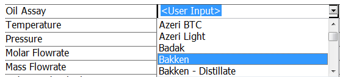

Additionally, the dropdown menu in the Oil Assay field contains a list of many commercial crude and constituent product assays.

In upcoming blogs, we will discuss how to simulate a hydroprocessing unit reactor by using the new Catalytic Fixed Bed block.

An easy way to become familiar with the new ProMax capabilities for refinery process simulation is to explore the AutoKinetic Reactors Examples folder where simulations for common processes are available to be used as templates to create your own models. Please be sure to call the BR&E Technical Support Team for further details and help in using these new Oil Speciation capabilities.

REFERENCES

Martinis, J.M., Solvason C.C. U.S. Patent App US 2016/0092660 A1, USPTO (2014).

Riazi, M.R. (2005) “Characterization and Properties of Petroleum Fractions”, ASTM, 1st Edition.